The CSTR is a fully mixed anaerobic reactor that maximizes contact between biomass and waste for efficient digestion. Suitable for a wide range of waste types, it offers flexible operation with various mixing and biogas retention options. Wastewater enters from the bottom, exits at the top, and is internally recirculated. A top-entry agitator ensures effective mixing, with alternatives like side or jet mixers available.

How We Can Help

- Low to medium loading rates.

- No waste is too strong (organic content, COD). The system can handle sludge, slurries or other concentrated waste waters.

- Suitable for high fats, oil and grease (FOG) concentrations.

- Can manage very high suspended solids (TSS) concentrations (25,000 mg/L TSS).

- CSTR– M (mesophilic digestion: 35-40°C) suitable for high protein (nitrogen) content wastes.

- CSTR– T (thermophilic digestion process: 45-55°C) suitable for low protein (nitrogen) content wastes.

The basic working principle of our H2S Removal System, the Scrubber can be viewed as a caustic type of Hydrogen Sulphide Removal System in which the spent caustic solution is continuously regenerated in a bio reactor.

H2S + OH → HS−liquid + H2O

The scrubbing liquid containing the sulphide is directed to the bio reactor where the sulphide is oxidized by aerobic microorganisms, of the group of the colourless sulphur bacteria, into the elemental bio sulphur.

HS− + ½ O2 → S0 + OH− (2)

The hydroxide used in the scrubber is regenerated biologically, allowing sulphide-free liquid to enter from the top, creating a high concentration difference between gas and liquid phases. This enables over 99% H₂S removal efficiency. The resulting sodium salt bleed stream is sulphide-free and usually safe for discharge. We have developed a nutrient feed to support microorganisms that convert hydrogen sulphide to elemental sulphur. Our biogas desulphurization system not only removes H₂S effectively but also produces elemental sulphur (80–90% purity) as a by-product. This sulphur can be used in fertilizers, firecrackers, or further purified (95–99%) via smelting for specialized uses in the sugar and pharmaceutical industries.

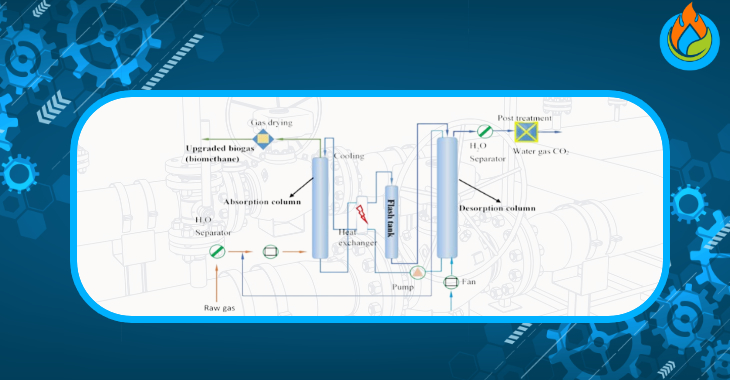

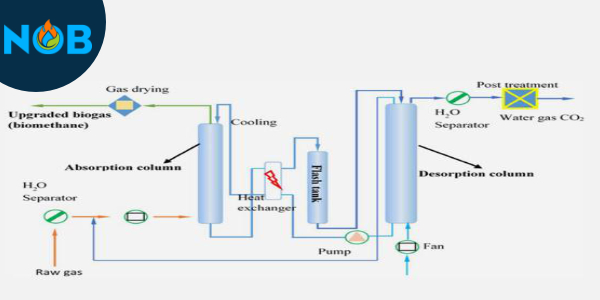

Water scrubbing is used to remove carbon dioxide but also hydrogen sulphide from biogas since these gases is more soluble in water than methane. The absorption process is purely physical. Usually, the biogas is pressurized and fed to the bottom of a packed column where water is fed on the top and so the absorption process is operated counter-currently.

Pressure swing adsorption, also known as PSA, is emerging as most popular biogas upgradation technology in many parts of the world. A typical PAS system is compressed of two or four vessels in series that are filled with adsorbent media which is capable of removing water vapour, Co2, N2 and O2 from the biogas stream.

The technology used to separate the two main components of biogas –methane and carbon dioxide – is based on the use of polymer membranes. This efficient system generated biomethane with a methane (CH4) content of between 96.5% and 99% depending on its purpose.

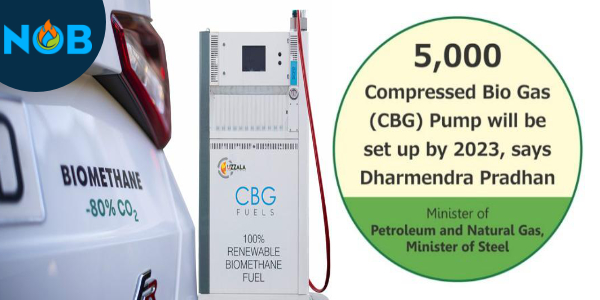

CBG is made from fermented waste or other biological material, thus making it a CO2 neutral fuel. The fuel is mostly made up of methane, the other approx. 5 percent is made up of various gases. Compressed Biogas (CBG) is becoming an important part of the offerings for CO2 neutral fuel for vehicles.

We provide CBG by following below parameters & specifications

- CBG will be free from liquids over the entire range of temperature and pressure encountered in storage and dispensing system

- The CBG will be free from particular matter such as dirt, dust etc.

- CBG delivered shall be odorized similar to a level found in local distribution

- Compressed Bio Gas (CBG) to be supplied shall meet IS 16087:2016 specifications of

- BIS (detailed below) and any other further revisions in the said specifications.

| IS 16087 : 2016 STANDARD | ||

|---|---|---|

| Sr. No. | Characteristics | Requirement |

| 1 | Methane Percentage (CH₄) Minimum | 90%* |

| 2 | Only Carbon Dioxide Percentage (CO₂) Maximum | 4% |

| 3 | Carbon Dioxide (CO₂) + Nitrogen (N₂) + Oxygen (O₂) Percentage Maximum | 10% |

| 4 | Total Sulphur (Including H₂S) mg/m³, Maximum | 0.5% |

| 5 | Total Sulphur (Including H₂S) mg/m³, Maximum | 20 mg/m³ |

| 6 | Moisture mg/m³, Maximum | 5 mg/m³ |

However Purity of Methane Percentage is up to 97%

Benefits of Compressed Bio Gas (CBG)

- Lowering pollution and carbon emission.

- Cheaper than other fuel.

- Import reduction of natural gas and crude

- Providing a buffer against energy security concerns and crude/gas price fluctuations.

- Providing additional source of revenue to the farmers, rural employment and amelioration of the rural economy.

- Contribution towards Swachh Bharat Mission through responsible waste management.

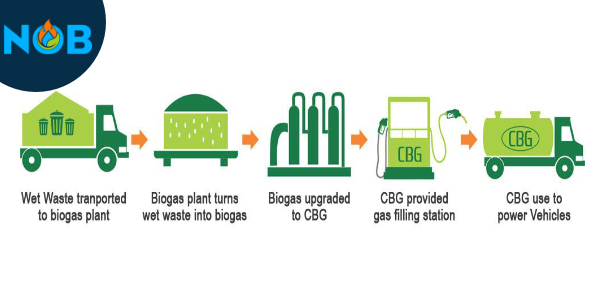

Transformation of organic waste into Compressed Biogas (CBG)

Biogas Generation from Sewage Sludge & Sewage Treatment Plant

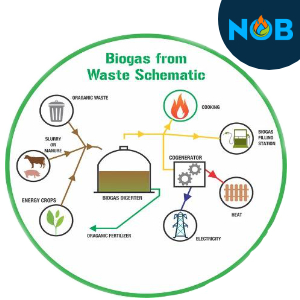

Biogas is generated through anaerobic digestion of organic materials like sewage sludge, animal waste, and municipal solid waste (MSW). Sewage sludge primarily contains proteins, sugars, lipids, detergents, phenols, and some toxic pollutants. Anaerobic digestion occurs in three stages: acidogenesis, acetogenesis, and methanogenesis. About 80–85% of biogas is produced within the first 15–18 days of a 30-day process. Optimal conditions include temperatures of 30–60°C and pH levels of 5.5–8.5. Sewage sludge typically has low nitrogen and a high C/N ratio (40–70), which can be balanced by adding nitrogen-rich materials like manure, urea, or food waste. A 500 m³ digester can yield approximately 20,000–36,000 Nm³ of biogas annually.

What we are willing to create a wastewater treatment plant that is, at a minimum, energy neutral, by minimizing the power used on site, and maximizing the production of biogas and energy from wastewater and organic waste.

Disposal and treatment of biological waste represent a major challenge for the waste industry. For a wide range of organic substances from agriculture, foodstuff of feed industries, anaerobic digestion is a superior alternative to composting. Biogas – a mixture of both methane and carbon dioxide – is created during anaerobic digestion and serves as a high-energy renewable fuel that can be used as a substitute for fossil fuels. Biogas-fuelled gas engines improve waste management while maximising the use of an economical energy supply.

ADVANTAGES OF BIOGAS PLANTS

-

DOMESTIC FUEL

DOMESTIC FUEL

-

FOR STREET LIGHTING

FOR STREET LIGHTING

-

GENERATION OF ELECTRICITY

GENERATION OF ELECTRICITY

-

IF COMPRESSED, IT CAN REPLACE

COMPRESSED NATURAL GAS CBG

IF COMPRESSED, IT CAN REPLACE

COMPRESSED NATURAL GAS CBG

Advantages of fixed dome type of biogas plant

- Requires only locally and easily available materials for construction.

- Inexpensive

- Easy to construct

Advantages of Biogas as Fuel

- High calorific value

- Clean fuel

- No residue produced

- No smoke produced

- Non polluting

- Economical

- Can be supplied through pipe lines

- Burns readily - has a convenient ignition temperature

Continuous Stirred-Tank Reactor (CSTR) Anaerobic Digester

The sludge from biogas production can be used as organic fertilizer which functions as plant growth stimulator and bio-fungicide. Biogas residue fertilizer is not only with high quality, but also a good soil conditioner. According to the determination, applying biogas organic fertilizer can increase soil 0.17-0.6% of organic matter content, enhance 0.003-0.005% of total nitrogen and improve 0.01-0.03% of total phosphorus.

Advantages of Organic Fertilizer

In addition to releasing nutrients, as organic fertilizers break down, they improve the structure of the soil and increase its ability to hold water and nutrients. Over time, organic fertilizers will make your soil–and plants–healthy and strong. There’s little to no risk of toxic buildups of chemicals and salts that can be deadly to plants. Organic fertilizers are renewable, biodegradable, sustainable, and environmentally friendly.

Benefits of Organic Fertilizer

- Food produced is free from harmful chemicals.

- Easily bio-degradable and do not cause pollution

- Help maintain soil structure, fertility & increase soil nutrient holding capacity.

- Easy to prepare in Garden or farm.